Fiber Optic Connectors: How to Choose From LC/FC/SC/ST/MU/MPO/MTP?

written by Asterfuison

Table of Contents

In the dynamic world of optical communication, one component that truly stands out is the fiber optic connector. This indispensable element acts as the crucial link between optical fibers (or cables) and communication modules, ensuring that signals are transmitted with stability and efficiency. By enhancing system performance and reducing costs, fiber optic connectors are vital to the success of modern communication systems. However, with a myriad of fiber optic connector types available, the technical terminology can often be daunting for newcomers. Let’s demystify these connectors and explore their various types and functions.

What is a Fiber Optic Connector?

A fibre optic connector is a device utilised for the interconnection of optical fibres. It facilitates the transmission and reception of optical signals between optical fibres via a physical interface. The primary function of a fibre optic connector is to facilitate the transmission of optical signals between optical fibres to the target device, thereby enabling high-speed, stable, and high-quality data transmission.

The Structure of a Fiber Optic Connector

A fiber optic connector is composed of four key components:

- Pin (Ferrule): This is a long, thin-walled cylinder where the fiber is mounted. The pin serves as an alignment mechanism, featuring a hole slightly larger than the fiber cladding. The fiber’s end is positioned at the pin’s tip, and while pins are typically made from metal or ceramic, plastic variants also exist.

- Connector Body: Also known as the connector shell, this part houses the pin. Made from metal or plastic, the connector body includes assembly parts that secure the fiber in place. The design can vary significantly between different connector models, but methods like welding or flanging are commonly used to attach strength members and cable jackets.

- Fiber Optic Cable: This cable connects to the connector body and serves as the entry point for the optical fiber. A strain relief boot is often added at the junction to enhance durability.

- Connector Mechanism: Unlike traditional male-female electronic connections, most fiber optic connectors utilize a positioning sleeve for mating. This allows for easy connection and disconnection, often referred to as pass-through bulkhead adapters.

How Fiber Optic Connectors Work?

When two optical fibers are joined via a connector, the pins align perfectly, enabling the optical signal to transmit continuously without loss. This process demands that the connector exhibits extremely low insertion loss and return loss, along with excellent repeatability and interchangeability

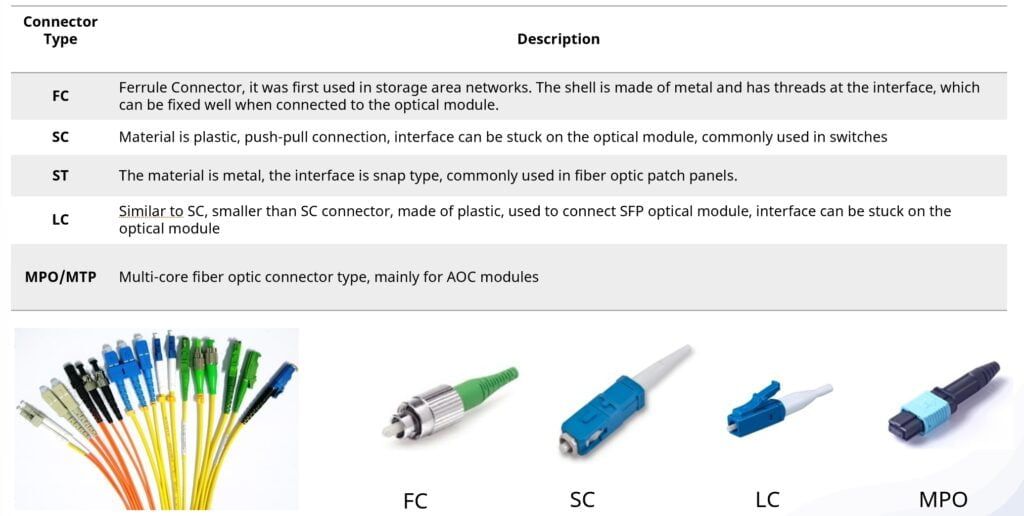

Classifications of Fiber Optic Connectors

Fiber optic connectors are the unsung heroes of optical communication, ensuring seamless data transmission across networks. Understanding their classifications can help demystify their roles and applications. Let’s dive into the four main ways these connectors are categorized:

1. Transmission Media: Single-Mode vs. Multi-Mode

Fiber optic connectors are primarily divided based on the type of transmission media they support:

- Single-Mode Connectors: These are designed for long-distance communication, offering high data rates with minimal signal loss. They are ideal for applications requiring precision and clarity over extended distances

- Multi-Mode Connectors: These connectors are suited for shorter distances, where multiple light paths can be utilized. They are cost-effective for local area networks and other short-range applications.

2. Structural Variations: A World of Models

The structural design of fiber optic connectors varies widely, with models such as ST, SC, FC, LC, MT-RJ, MPO/MTP, MU, DIN, E2000, SMA, BICONIC, and D4. Each model has unique features tailored to specific applications

3. Pin End Surface: PC, UPC, and APC

The pin end surface of a connector affects its performance and is categorized into:

- PC (Physical Contact): Offers a basic level of performance with a flat surface.

- UPC (Ultra Physical Contact): Provides better performance with a slightly curved surface to reduce signal loss.

- APC (Angled Physical Contact): Delivers the highest performance with an angled surface to minimize reflection and signal degradation.

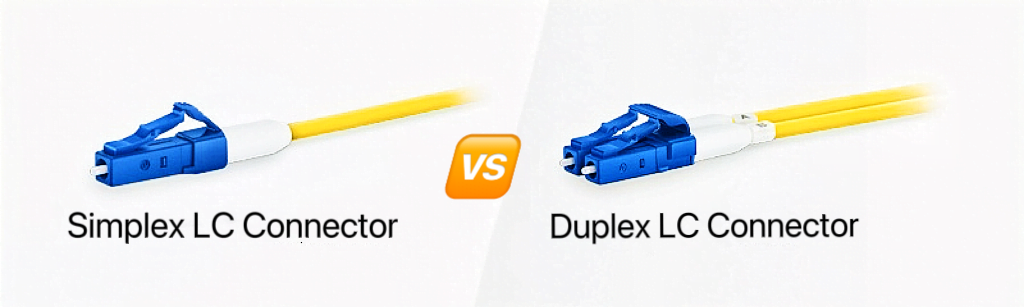

4. Fiber Core Count: Single vs. Multi-Fiber

Connectors are also classified by the number of fiber cores they accommodate:

- Single-Fiber Core Connectors: Used for individual fiber connections, offering simplicity and ease of use.

- Multi-Fiber Core Connectors: Such as MPO/MTP, these connectors can handle multiple fibers simultaneously, making them ideal for high-bandwidth applications

Spotlight on the Most Popular Connectors

While there are over 100 types of fiber optic connectors, a few dominate the market due to their versatility and performance. Let’s explore some of the most popular types of connectors and their unique features.

LC Connector: The Compact Powerhouse

The LC connector, short for “Lucent Connector,” was pioneered by Bell Labs in the USA. Its standout feature is the 1.25mm pin and sleeve, which is half the size of traditional connectors like SC and FC. This compact design makes LC fiber optic connectors ideal for high-density environments such as data centers and residential installations. The easy-to-use pull-tab mechanism allows for quick installation and removal, minimizing the risk of cable damage.

LC connectors are celebrated for their versatility and low insertion loss, making them a top choice for both single-mode and multimode fiber networks. Their popularity continues to rise in high-speed communication applications due to their efficient performance and space-saving design.

-

400G FR4 QSFP112 1310nm 2km Optical Transceiver Module

400G FR4 QSFP112 1310nm 2km Optical Transceiver Module -

400G LR4 QSFP-DD 1310nm 10km Optical Transceiver Module

400G LR4 QSFP-DD 1310nm 10km Optical Transceiver Module -

400G FR4 QSFP-DD 1310nm 2km Optical Transceiver Module

400G FR4 QSFP-DD 1310nm 2km Optical Transceiver Module -

100GBASE ZR4 QSFP28 LAN WDM 80km Optical Transceiver Module

100GBASE ZR4 QSFP28 LAN WDM 80km Optical Transceiver Module -

100GBASE ER4 QSFP28 LAN WDM 40km Optical Transceiver Module

100GBASE ER4 QSFP28 LAN WDM 40km Optical Transceiver Module -

10GBASE-LR SFP+ 1310nm 10km Optical Transceiver Module

10GBASE-LR SFP+ 1310nm 10km Optical Transceiver Module

SC Connector: The Reliable Workhorse

Developed by NTT Corporation of Japan, the SC connector (Square Connector) features a robust rectangular shell made from molded fiberglass plastic and a 2.5mm ferrule. Known for its reliability, the SC fiber connector is a staple in fiber optic networks, particularly in patch panels and wall plates.

SC fiber optic connectors are renowned for their high pulling force and push-pull interface, which makes them suitable for high-density installations. They were among the first low-cost, high-performance connectors on the market and are primarily used in single-mode applications, though they also find use in some multimode networks.

ST Connector: The Classic Choice

The ST connector (Straight Tip) is one of the earliest fiber optic connectors, featuring a BNC-like bayonet locking mechanism for secure connections. While reliable and simple, the ST fiber optic connector’s bulky design and susceptibility to dust contamination have led to a decline in popularity. Nevertheless, it remains a viable option for long-distance and short-distance applications, including campus networks and military installations.

FC Connector: The Industrial Standard

The FC connector (Ferrule Connector) was also developed by NTT Corporation and is known for its screw-locking mechanism, providing high tensile strength. This makes the FC fiber connector ideal for industrial and harsh environments where a stable, high-performance connection is crucial. However, its larger size can be a drawback in high-density applications.

MU Connector: The Miniature Marvel

The MU connector (Miniature Unit) is a smaller version of the SC connector, designed for high-density applications like data centers. Its compact size is advantageous in space-constrained environments, though it requires careful handling during installation to avoid damage.

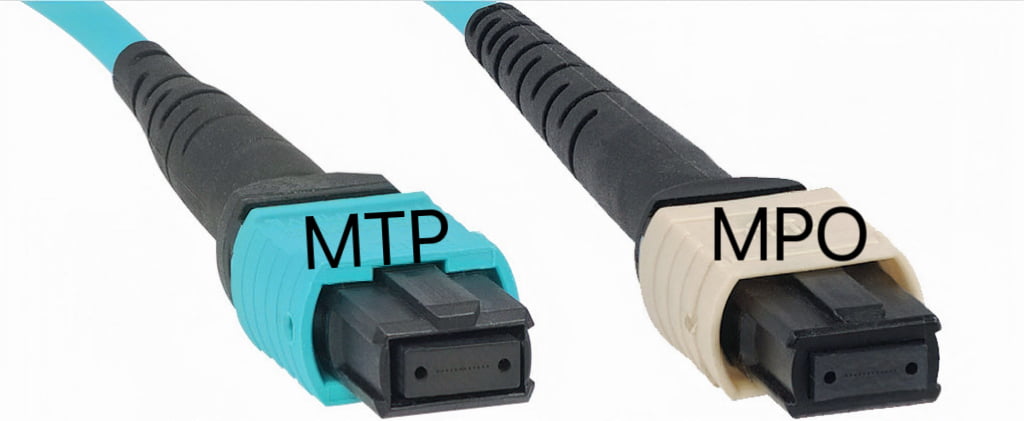

MPO Connector: The Multi-Fiber Solution

The MPO connector (Multi-fiber Push On) is a multi-fiber connector designed by NTT Corporation, capable of connecting up to 12 optical fibers. MPO fiber connectors’ modular design and high-density capabilities make it a popular choice for large data centers and telecommunications networks.

MTP Connector: The Enhanced Performer

The MTP connector (Multi-fiber Termination Push-on) is an advanced version of the MPO connector, offering superior mechanical and optical performance. With the ability to connect up to 72 optical fibers, MTP fiber optic connectors are ideal for high-speed data transmission in data centers. Their fast and simple installation process makes them a preferred choice for high-performance computing and telecommunications networks.

Choice Between Single-Mode vs. Multi-Mode Fiber Optic Connectors

The choice between single-mode and multimode fiber optic connectors depends on the specific requirements of your network, such as distance and bandwidth needs.

Single-Mode Fiber Optic Connectors

Single-mode fiber optics are characterized by their smaller core size, typically around 9 microns, which allows them to transmit data over long distances with minimal signal loss. This makes them ideal for high-speed, long-distance networks. Here are some common single-mode connectors:

- SC Connectors: Known for their square ferrules, SC connectors provide excellent alignment and low insertion and return losses, making them a popular choice for single-mode applications.

- LC Connectors: These are smaller and easier to use, making them suitable for high-density environments like data centers.

- FC Connectors: Rugged and reliable, FC connectors are used in applications requiring high precision and performance

Multimode Fiber Optic Connectors

Multimode fiber optics have a larger core size, typically 50 or 62.5 microns, which allows them to carry multiple light modes. This makes them suitable for shorter distances, such as within a building or campus. Common multimode connectors include:

- SC Connectors: These are also used in multimode applications, with ceramic ferrules that ensure precise core alignment and reduce back reflections.

- ST Connectors: Featuring a twist-on, twist-off mechanism, ST connectors are easy to use but not as compact as other types.

- LC Connectors: Like their single-mode counterparts, LC connectors are small and easy to use, ideal for high-density environments.

Choosing the Right Connector for Your Application

When selecting a fiber optic connector, consider the following:

- Distance: For long-distance applications, single-mode connectors are preferable due to their ability to maintain signal integrity over greater distances

- Bandwidth: If high bandwidth is a priority, single-mode fibers are generally more suitable.

- Environment: For high-density environments, such as data centers, LC connectors are often the best choice due to their compact size.

By understanding the differences between single-mode and multimode fiber optic connectors, you can make an informed decision that best suits your network’s needs.

For More Information about Optical Modules, Please Refer To:

800G Optical Modules: Everything You Need to Know in This Article

The Most Comprehensive Guide of Optical Modules

Buying Guide of Ethernet cable: Cat5, Cat5e, Cat6, Cat6a, Cat7, and Cat8

The Most Complete Overview of Multimode Fibres -OM1, OM2, OM3, OM4 & OM5